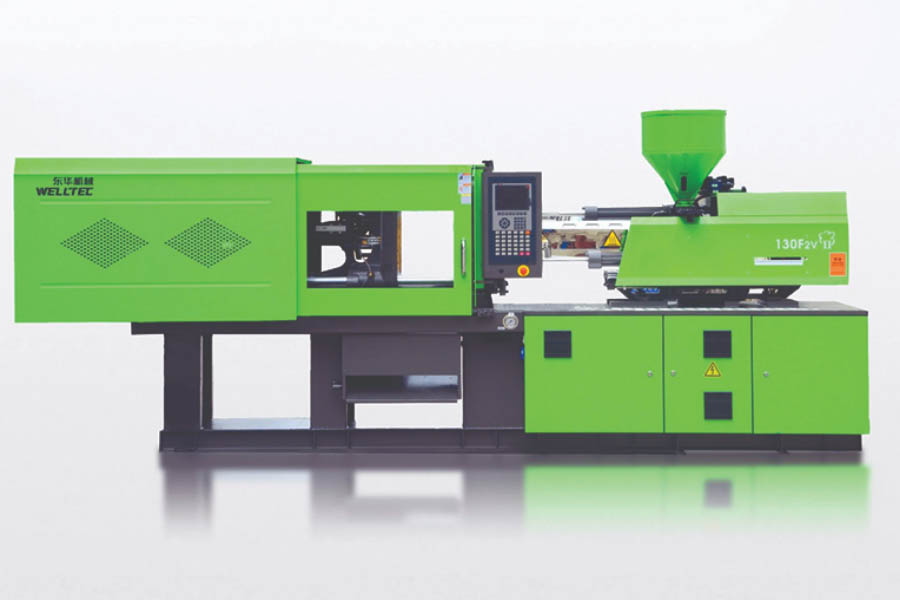

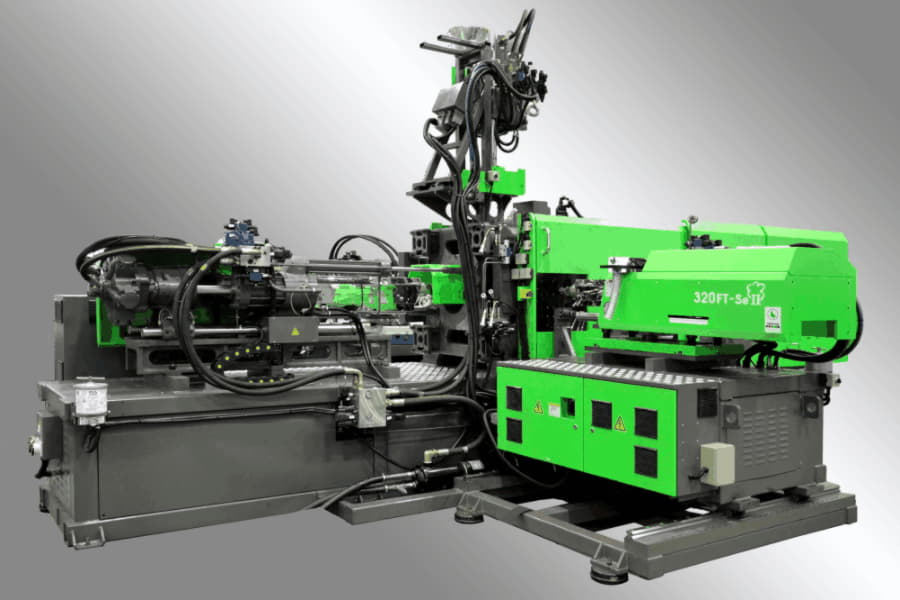

Clamping Unit

- Compact space saving toggle mechanism design;

- Finite Element Analysis ensures all platens for their maximum service life and best moulding results;

- Advanced stress analysis software is applied to design of tie bars and their lock nuts;

- More smooth and stable mould closing,opening and mould thickness adjustment

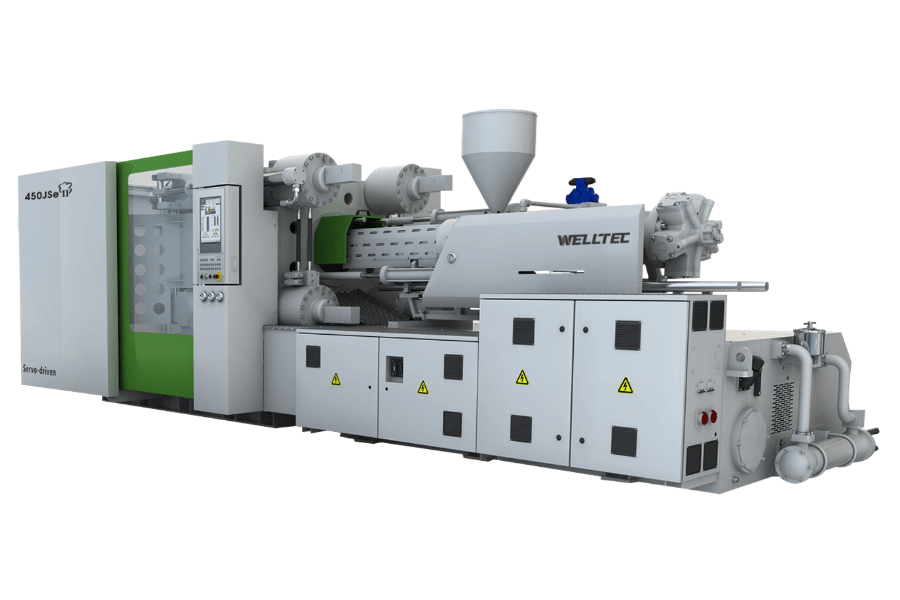

Hydraulic System

- New design of hydraulic circuit,easy for maintenance;

- Saving about 30%-50% of electricity compared with standard fixed vane pump;

- Low heat generated in hydraulic system and 30% cooling water volume can be reduced;

- Bypass filter device will ensure the hydraulic oil in a high cleanliness

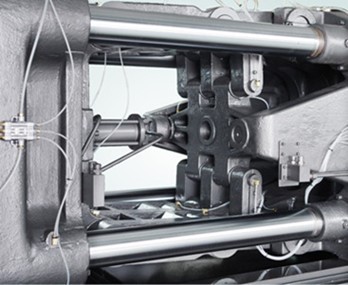

Injection Unit

- Creative design of injection unit;

- High flexiblility to match and change different diameter screws;

- Diagonal layout of carriage cylinders to balance the supporting force (Above 90F2VII);

- Screw and barrel are made of high quality new mate-rials,improved their working life;

- Anit-wear bushes are replaced by copper bushes,which improve the lubrication effect;

- Four-stage injection speed and pressure setting;

- Four-stage holding pressure setting;

- Three-stage metering speed and pressure setting

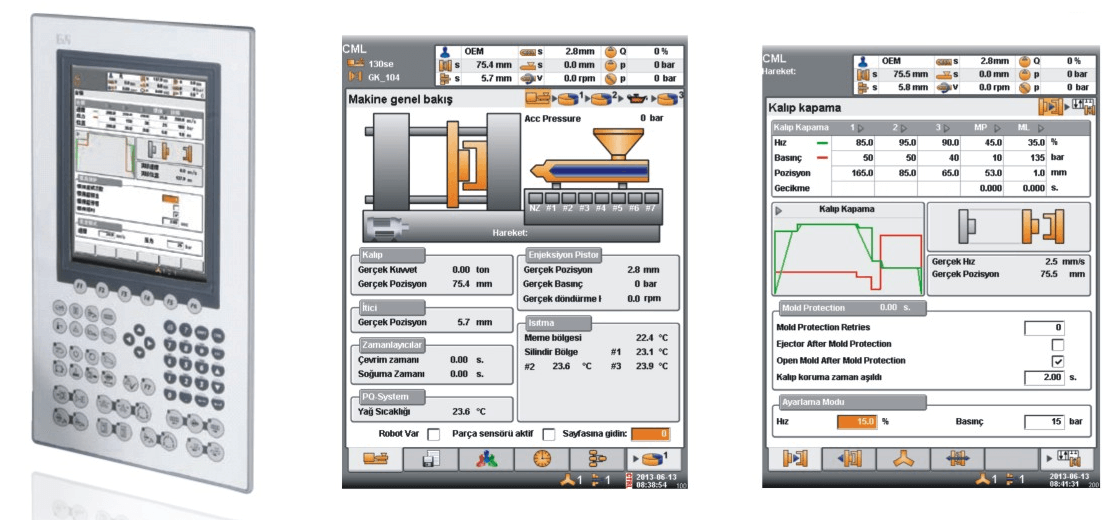

Control System

- TFT colour 8’’ 800*600 display;

- PLC response time 1ms-2ms;

- External storage on USB or SD card;

- 8 temperature channels with Autotuning PID control;

- Decompression before plastification and Suck back after plastification;

- Screw rotating speed display;

- Auto-purge;

- Barrel heating schedule;

- 100 setes mould data storage,200 sets mould data storage on external USB device (Option);

- Chinese/English real time display on screen;

- 4 leveles password for data protection;

- SPC quality management