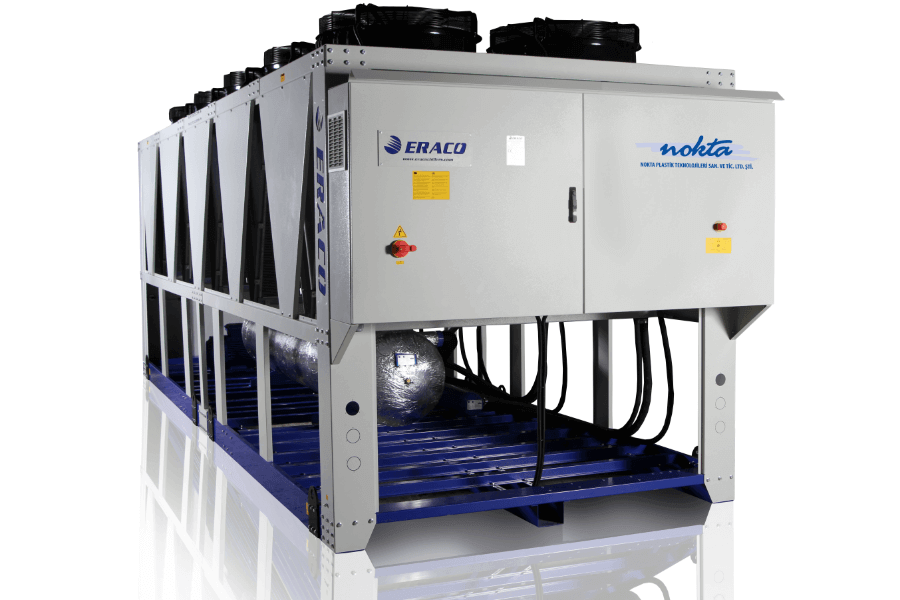

General Features

Free Coolers ( Dry Coolers ) are used to cool down the cycling fluid by the ambient air condition. High performance Free Coolers are manufactured with copper tubes and corrugated aluminum fins which improve heat transfer coefficient and they are available for vertical and horizontal airflow. Being manufacturing with 1/2” or 5/8” copper tubes, V type Dry-Coolers are available with a capacity range of 583 kW to 2026 kW; also available to produce in special design and different conditions.

Free Coolers has a suitable structure for parallel connection; thus the cooling plants could be comfortably increased by connecting capacity using with NKT.FCV series Free Coolers.

Technical Information

- V type design.

- Structures are galvanized steel painted with polyester based electrostatically powder; to avoid corrosion and UV ray effect.

- Each two fans are separated by internal baffle plates from other each chamber to avoid energy loss causing by reverse fan rotation.

- Each fan chamber has own maintenance covers.

- Tested at 20 bar pressure.

- Suitable for outdoor installation; motor protection IP 54.

- Suitable to work up to +60°C ambient temperature.

- Guaranteed to long-lasting life due to high corrosion resistant materials.

- Totally closed loop circuits prevent fouling and calcification.

- Automatic air and water discharge valve ( standard ).

- Microprocessor controls the fan rotation in terms of stepwise control according to the ambient temperature and set water temperature.

- Automatic water mistspraying systems provide adiabatic cooling affect which allows pulverizing the water on to the fresh air before entering to heat exchanger. System decreases the entering air temperature adducted to the wet bulb temperature.

- Units are equipped with error codes and visually alarm system leading by microprocessor.